Máquina formadora de puertas de persiana enrollable de acero

- Lugar de origen:

- porcelana

- Capacidad de suministro:

- 20set/Mouth

- Certificados :

- CE, ISO

Información básica

Modelo: WLFM

Descripción del producto

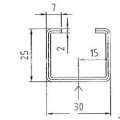

Modelo NO.: WLFM Condición: Nuevo Uso: Bobina de puerta THK: 0.6-0.8 Estación de rodillos: 13-14 Potencia hidráulica: 3kw Material del rodillo: # 45 HRC: 58-60 Marca registrada: WILLINGIN'T Especificación: CE & ISO9001 Certificación: CE, ISO Personalizado: Método de transmisión personalizado: Presión hidráulica Ancho de la bobina: 198 Potencia del motor principal: 4kw Diámetro del eje: 70 mm Material del cortador: Placa de pared Cr12 THK: 16 mm Paquete de transporte: Cajas de madera Origen: China Máquina formadora de rollos de puerta de persiana \ n \ n Componentes para la máquina \ n La máquina perfiladora consta de un desenrollador manual de 3 toneladas, una guía de alimentación, estaciones de conformado accionadas por posición fija, dispositivo rectificador, equipo de corte, estación hidráulica, consola de control PLC y mesa de descarga manual de salida de producto . \ n \ n Material del equipo principal

\ nComponente y función:

\ n Boceto del proceso: \ nDesenrollado de la hoja -Guía de entrada -Conformado en rollo -Medida de largo - Rectificación -Cortando el panel - Paneles al soporte (opción: apilador automático). \ n \ nMuestra de aplicación: \ n \ nEquipo estándar de la máquina:

\ nSomos un fabricante en China \ npodemos fabricar la máquina según su solicitud. \ nAcerca de la máquina, \ nnecesitamos que nos proporcione información, \ n1. dibujo de perfil y tamaño del producto (modelo), \ n2. rango de espesor de acero, \ n3. ancho de la bobina, \ n4. tensión del acero, \ n5. requisitos para la configuración. \ n \ nPara el precio y otros detalles, le invitamos a consultarnos. \ n \ nPonte en contacto con la Srta. Lucy \ n

| Roller Material | High grade S45C forged steel, coated with hard chrome. |

| Active Shaft Material | High grade S45C carbon wrought steel, diameter 76mm. |

| Electric Elements | PLC control console, touch screen and transducer, from Siemens, Germany. Other elements, from Schneider Electric, Germany. |

| Cutter Bladespt | Cr12MoV steel with quenched treatment, hardness HRC58~61, wear-resistance, good steel structure, long life. |

| Coil Feeding Equipment | Consists of one uncoiler with capacity of 3 tons and its base. The steel sheet is manually fed to the guiding equipment under the function of friction and traction. |

| Infeed Guide | Adopting guiding bar and sliding block (sheet lubricator) to control the width and position of the steel sheet. The coil sheet is guided in the correct position and passed to the roll forming equipment. |

| Mainframe Transmission | Transfer the main motor power to the rollers through cardan gear, and also transfer the coil sheet.rrect position and passed to the roll forming equipment. |

| Roll Forming Station- | The main frame of machine is welded separately and the outside wall is connected by screw after being roto blasted on the surface. The rollers are surface-chrome plated after being machined by the exact machine tool. The tooling is PLC precision machined and supported with pre-lubricated rolling contact bearings. |

| Rectifying Device | Used upper 2 rollers and lower 3 rollers, to rectify the straightness of the panel after roll formed. |

| Post-cut Equipmentn> | Stationary hydraulic post shear/guillotine. The length and quantity of pieces can be set by the buyer through the control console, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. |

| Hydraulic Station | Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power. |

| PLC Control Console | The electric controlling system of this machine consists of five parts: operating system, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens Company of Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutualdialogue between the operator and the machine. The operation is easy and steady and can be chosen operation by manual or automatically. |

| Product Support Table | To support the finished run out panels. The quantity we supply is 2 pieces with length 2 meters; it can support panels with more than 4 meters in normal condition. |

| 1 | Manual Uncoiler | 1set |

| 2 | Infeed Guide | 1set |

| 3 | Roll Forming Station | 1set |

| 4 | Rectifying Device | 1set |

| 5 | Post-cut Equipment | 1set |

| 6 | Hydraulic Station | 1pc |

| 7 | PLC Control Console | 1pc |

| 8 | Product Support Table | 2pcs |

| 9 | Spare Parts | 1box |

Grupos de Producto : Línea de formación de teja de techo modular

Premium Related Products

Otros productos

Productos hot

Tile que forma la máquina (WLFM28-207-828)Máquina de colocación (WILLING)Máquina de pared seca (WLFM-C80-U82)Roll que forma la máquina (WLFM18-76-988)C Purlin que forma la máquina (WLCM-1)Rodillo del soporte de energía solar que forma la máquinaÚnica capa de CNC Color de acero formando máquina / acero curvado máquina de curvarÚnica capa de acero CNC de color que forma la máquina Undulator / metal panel panel de techoRollo de acero de color de una sola capa de color CNC que forma la máquina / rollo de panel de techo automático que forma la máquinaEl nuevo CNC de alta velocidad cortó el rodillo de acero de C que hace la máquina que hace la máquina que hace la máquinaLínea de producción semiautomática de morteroUna sola capa de CNC Color rodillo de acero que forma la máquina / máquina de prensa de acero / máquina de azulejos de techoHGC60-221-845B rodillo de acero del color del CNC de la sola capa que forma la máquina / el formar del azulejo de la azoteaGalvanizado de la hoja del material para techos que forma la máquina / las máquinas de la forma del rodillo del azulejo / la azotea que forma la máquinaLínea de producción de acero compuesto de color / chapa metálicaLleno automático C purlin / Z purlin rodillo que forma la máquina