Máquina perfiladora de techos de acero de metal con alta calidad

- Lugar de origen:

- porcelana

- Capacidad de suministro:

- 20set/Mouth

- Certificados :

- CE, ISO

Información básica

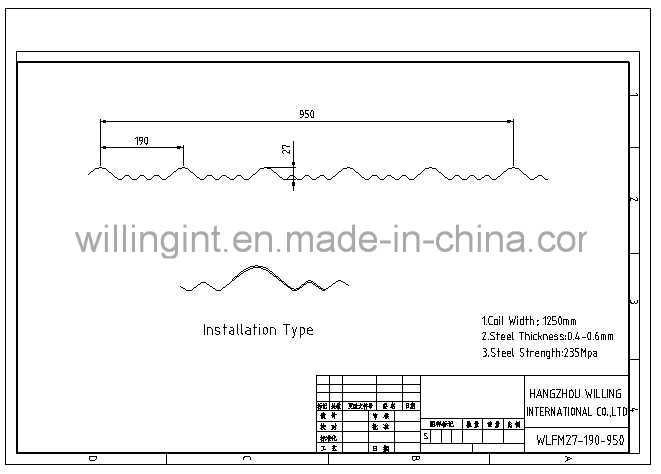

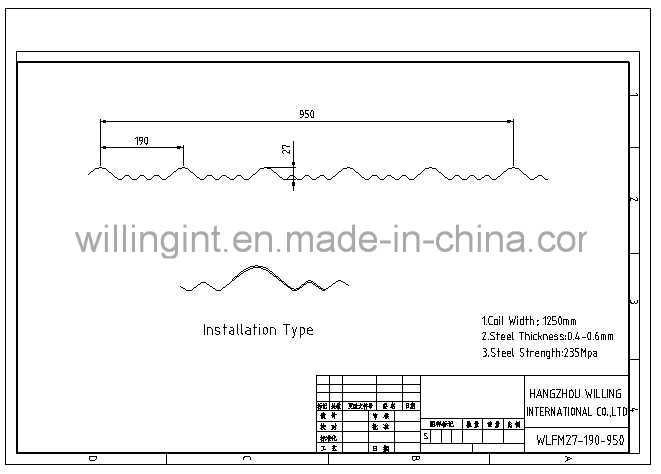

Modelo: WLYX27-190-950

Descripción del producto

No. de modelo: WLYX27-190-950 Condición: Nuevo Personalizado: Personalizado Fuente de energía: Eléctrico Tipo de producto: Máquina formadora de rollos Ancho de la bobina: 1200 Potencia del motor principal: 5.5kw Diámetro del eje: 75 mm Material del cortador: Placa de pared # 45 THK : Paquete de transporte de 16 mm: Cajas de madera Origen: China Certificación: CE, ISO Diseño de tornillo: Tornillo doble Aplicación: Placas, maquinaria y hardware Grado automático: Bobina automática THK: 0.4 ~ 0.6 Estación de rodillos: 17 Potencia hidráulica: 5.5kw Material de Rodillo: # 45 HRC: 58-60 Marca registrada: WILLING Especificación: Máquina perfiladora de tejas de acero CE e ISO \ nComponentes de la máquina: \ nLa máquina perfiladora incluye una unidad de desenrollador manual, guía de alimentación, estaciones de conformado accionadas por posición fija, troquel de prensado, equipo de corte, estación hidráulica, consola PLC y mesa de descarga manual de producto. \ n \ n \ n

\ nComponentes de la máquina: \ nLa máquina perfiladora incluye una unidad de desenrollador manual, guía de alimentación, estaciones de conformado accionadas por posición fija, troquel de prensado, equipo de corte, estación hidráulica, consola PLC y mesa de descarga manual de producto. \ n \ n \ n \ nDocumentos de envío: \ n1) Conocimiento de embarque, un juego completo; 2) Factura comercial, triplicación, 3) Lista de empaque, triplicación. \ N \ n Componente y función:

\ nDocumentos de envío: \ n1) Conocimiento de embarque, un juego completo; 2) Factura comercial, triplicación, 3) Lista de empaque, triplicación. \ N \ n Componente y función:

Embalaje y envío \ n \ n1.Un contenedor de 40 pies para cargar una máquina con desbobinador manual; 2.Todo el aceite antióxido limpiado, controlador PLC cubierto por una película de espuma; 3. Repuestos y algunas piezas pequeñas empaquetadas en caja de herramientas de plástico; 4.Todos los componentes fijados por alambre de acero con contenedor.FAQ Q: ¿Es usted un fabricante? R: Sí, absolutamente. Bienvenido mucho por su visita a nosotros. P: ¿Cuál es el tiempo de entrega? R: Normalmente tomará 60 días P: ¿Tiene soporte postventa? R: Sí, siempre estamos aquí para brindarle asesoramiento y soporte para los detalles técnicos, ya que contamos con un técnico superior. P: ¿Existe control de calidad al fabricar las líneas? R: Sí, tenemos un grupo de equipo que será responsable del control de calidad desde el despido de la materia prima, el procesamiento de los rodillos y las otras partes, el tratamiento en la superficie y el eje del rodillo, el montaje, las pruebas y el embalaje. P: ¿Cuál es su fortaleza en comparación con el otro proveedor? R: Le proporcionaremos la mejor calidad y servicio. Le daremos un buen asesoramiento más allá de sus requisitos. Las líneas son de fácil instalación y con bajos requerimientos de mantenimiento.

\ nComponentes de la máquina: \ nLa máquina perfiladora incluye una unidad de desenrollador manual, guía de alimentación, estaciones de conformado accionadas por posición fija, troquel de prensado, equipo de corte, estación hidráulica, consola PLC y mesa de descarga manual de producto. \ n \ n \ n

\ nComponentes de la máquina: \ nLa máquina perfiladora incluye una unidad de desenrollador manual, guía de alimentación, estaciones de conformado accionadas por posición fija, troquel de prensado, equipo de corte, estación hidráulica, consola PLC y mesa de descarga manual de producto. \ n \ n \ n \ nDocumentos de envío: \ n1) Conocimiento de embarque, un juego completo; 2) Factura comercial, triplicación, 3) Lista de empaque, triplicación. \ N \ n Componente y función:

\ nDocumentos de envío: \ n1) Conocimiento de embarque, un juego completo; 2) Factura comercial, triplicación, 3) Lista de empaque, triplicación. \ N \ n Componente y función:| Coil Feeding Equipment | Consists of one uncoiler with capacity of 5 tons and its base. The steel sheet is manually fed to the guiding equipment under the function of friction and traction. | ||||

| Infeed Guide | Adopting guiding bar and sliding block (sheet lubricator) to control the width and position of the steel sheet. The coil sheet is guided in the correct position and passed to the roll forming equipment. | ||||

| Mainframe Transmission | Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet.ition and passed to the roll forming equipment. | ||||

| Roll Forming Stationt. | The main frame of machine is welded separately and the outside wall is connected by screw after being roto blasted on the surface. The rollers are surface-chrome plated after being machined by the exact machine tool. The tooling is PLC precision machined and supported with pre-lubricated rolling contact bearings. | ||||

| Post-cut Equipment | Stationary hydraulic post shear/guillotine. The length and quantity of pieces can be set by the buyer through the control console, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. | ||||

| Pressing Die System | To make pressing die for the steel sheet after roll formed, the shape of corrugated sheet will be pressed into steps. The distance of step length can be adjusted.e power of hydraulic station which guarantees the precision of cutting. | ||||

| Hydraulic Station | Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power.length can be adjusted.e power of hydraulic station which guarantees the precision of cutting. | ||||

| PLC Control Console | The electric controlling system of this machine consists of five parts: operating system, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosenoperation by manual or automatically.ystem, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosenoperation by manual or automatically.ystem, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosenoperation by manual or automatically.ystem, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosen operation by manual or automatically.gth 2 meters; it can support panels with more than 4 meters in normal condition.ens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosen operation by manual or automatically. | ||||

| Product Support Table | To support the finished run out panels. The quantity we supply is 2 pieces with length 2 meters; it can support panels with more than 4 meters in normal condition.ens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosen | ||||

Grupos de Producto : Linea Corrugada / Trapezoidal

Premium Related Products

Otros productos

Productos hot

Tile que forma la máquina (WLFM28-207-828)Máquina de colocación (WILLING)Máquina de pared seca (WLFM-C80-U82)Roll que forma la máquina (WLFM18-76-988)C Purlin que forma la máquina (WLCM-1)Rodillo del soporte de energía solar que forma la máquinaÚnica capa de CNC Color de acero formando máquina / acero curvado máquina de curvarÚnica capa de acero CNC de color que forma la máquina Undulator / metal panel panel de techoRollo de acero de color de una sola capa de color CNC que forma la máquina / rollo de panel de techo automático que forma la máquinaEl nuevo CNC de alta velocidad cortó el rodillo de acero de C que hace la máquina que hace la máquina que hace la máquinaLínea de producción semiautomática de morteroUna sola capa de CNC Color rodillo de acero que forma la máquina / máquina de prensa de acero / máquina de azulejos de techoHGC60-221-845B rodillo de acero del color del CNC de la sola capa que forma la máquina / el formar del azulejo de la azoteaGalvanizado de la hoja del material para techos que forma la máquina / las máquinas de la forma del rodillo del azulejo / la azotea que forma la máquinaLínea de producción de acero compuesto de color / chapa metálicaLleno automático C purlin / Z purlin rodillo que forma la máquina